Please Excuse me - having some web hosting plan issues - in process of updating said hosting

Thanks -Jake

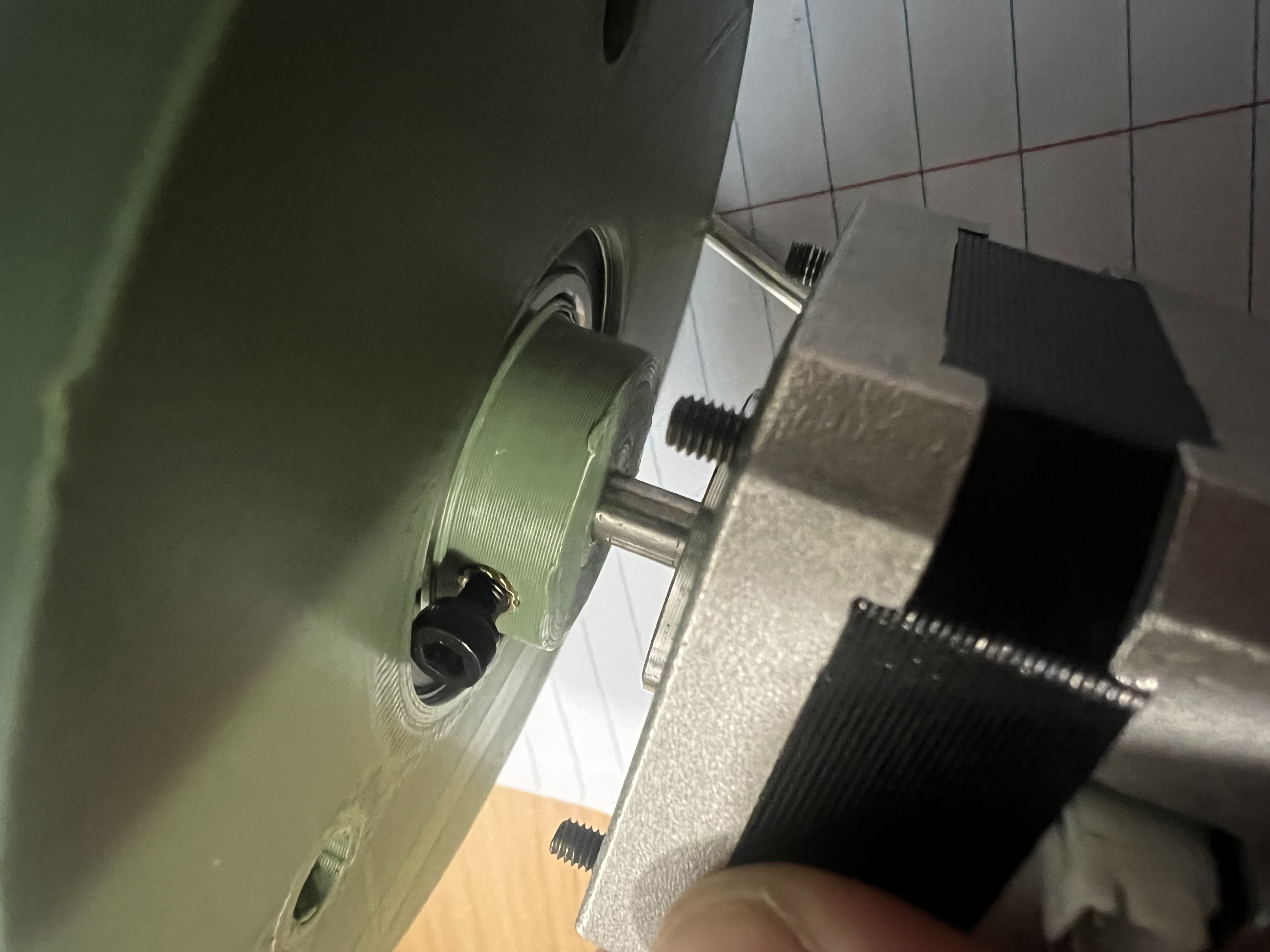

Planetary Gear Box

Iteration

I learned so much in the proces of making this. It was fun, exciting, and somewhat challenging.

Step One

I had to learn CAD I had zero experience. I had used tinkercad a bit but it's only rudimentary tools, and

to create anything robust you had to get creative and it took a lot of time.

So I decided to jump in and learn Fusion 360. I was able to get a huge discount and there is tons of

content for anyone curious about the process. Some of it can

be really intuitive but other things don't make much sense until you've built thru the process multiple

times. I found an amazing teacher on Youtube, his name is @Antalz. He jumps straight

in and start modeling, then he takes his time and explains the math behind it. The gear sets are some

algebra and trig, but there are scripts to create the module of gears you are looking for.

I learned a lot about the dimensions of planetary gear sets, how to calculate the center distance needed

by using the pitch dimeters of different gears. Can't thank that channel enough.

Step Two

This is where I began modeling. As you will see in the photos above I took my time. There were about 3

prints with the white PLA using my creality printer. First I tried to simple use some cylinders to hold

the bearings

to make sure that I was within spec. I needed them to print precisely where they were calculated to be

otherwise the gears would not mesh well, nor fit inside the ring gear.

This wasn't too bad but the biggest problem in the first iteration was the printing learning curve. Say

you print a module 1 gear with a backlash of .15mm. Then you print the same module gear with .2mm

backlash. Well

a lot of the time they would come out almost the exact same and this wouldn't account for the

tolerances. So I to make drastic changes either too much or too little until I found the sweet spot my

printer could produce.

I could have easily used a larger module for the gears but I wanted this to be somewhat precise without

as much backlash. This took the longest, besides the printing which is basically a passive activity.

Step Three

After I had a gear set I had tested I decided to bring out the more expensive material for printing.

Which is Sunlu PLA+. It's not amazing but it is a little strong, prints a little hotter, and can hold in

the brass inserts a little better than the

standard PLA. After I had that, it was time to design the housing, carrier plate, and decide which

hardware and components to order. I did this retroactively in a sense, I found what dimension bearings

were on amazon, then designed around those constraints.

I could have used McMaster-Carr but they are extremely expensive and sometimes it's the same bearing for

a fraction of the cost. I bought some brass inserts so I wouldn't need more space for nuts on both sides

of each component, and a variety pack of m4 bolts and washers.

It really is amazing what can get to your home in a couple of days, we have incredible access to so much

it really is inspiring.

Step Four

The last step was creating the housing. This was the easiest part as I knew my constraints and I knew the

dimensions of the output bearing. It's a very simple design right now. The middle section which is the

ring gear holds the brass inserts

this allows the input housing and output housing the simply bolt on from either side. I have also

attached some renders of the project in the carousel.

I am planning on redesigning with similar inputs and outputs but I want to make it as small as I can and

still get a ~5:1 reduction. The stepper motors I have are extremely weak so I plan on ordering some that

can lift a little more.

Once that is done I want to create a fairly large robotic arm and begin to program it, attach a camera

with computer vision so I can really learn more about the space. This has been a really fun hobby and

I'm even considering an embedded engineer

career path. If you have any questions feel free to reach out. Thanks!